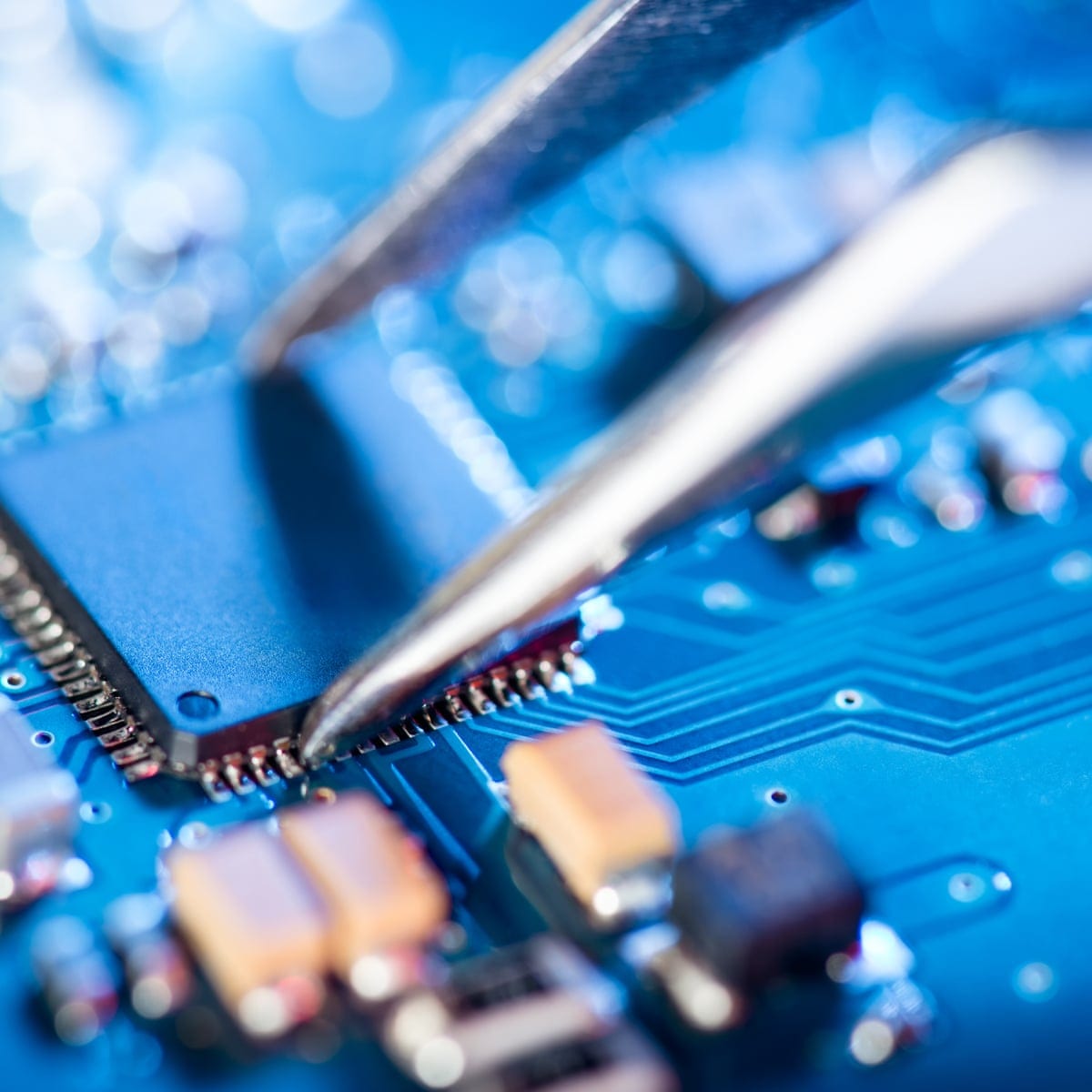

Pat Gelsinger, the CEO of Intel Corp., is not optimistic about any pending end to the global chip shortage – and he has a vested interest in the truth.

In fact, Gelsinger believes the dearth of vital chips could continue for several years and, until the global shortage of semiconductors is resolved, the worldwide supply chain will be affected.

That has already been the case, given the closings at auto production lines and myriad concerns in the cellphone and consumer electronics industries.

Gelsinger held a virtual conference affiliated with the Computex trade show in Taipei, and underscored the reasons for increased demand.

He said the pandemic led to an explosion in remote work and remote learning, giving way to a “cycle of explosive growth in semiconductors” that has placed major strains on global supply chains.

“But while the industry has taken steps to address near term constraints,” he said, “it could still take a couple of years for the ecosystem to address shortages of foundry capacity, substrates and components.”

As for the time frame, Gelsinger already had told the Washington Post in April the shortage was unlikely to be eased at least for “a couple of years,” and that, to address U.S. auto plant shortages, his company would begin producing chips within six to nine months.

In March, Intel unveiled a $20 billion investment plan for its advanced chip manufacturing, with a primary focus on two new facilities in Arizona.

“We plan to expand to other locations in the U.S. and Europe, ensuring a sustainable and secure semiconductor supply chain for the world,” Gelsinger said.

According to a Semiconductor Industry Association report referenced in a Fox Business story, U.S. semiconductor manufacturing capacity has fallen to 12% of global output, down from 37% in 1990.

Add comment